Product General Information:

| Place of Origin: | China |

| Brand Name: | NANTAI |

| Model Number: | AP-1060-TSB; AP-1060-TBS |

| Certification: | Automatic Flatbed Die Cutter |

Description:

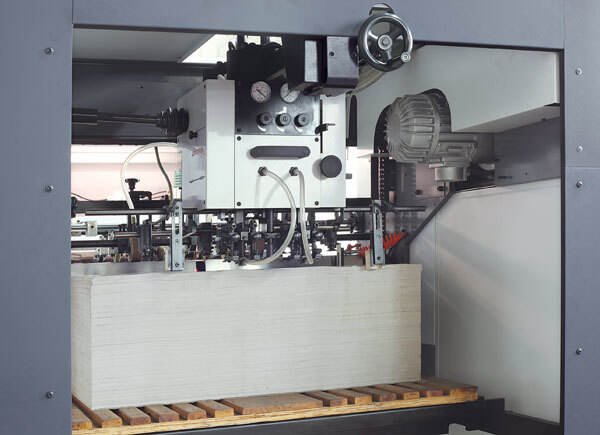

AP-1060-TSB Characteristics

*Suitable for die cutting thin paper, cardboard, laminating paperboard and corrugated board (G~B flute), high precision multi functional devices and options, it’s a long-term best selling model with two kinds of transfer modes of Gripper.

AP-1060-TBS Characteristics

Two kinds of transfer modes (TS, TSB) of Gripper are for optional, the Key technology in die cutting accuracy (Die cutter section has equip with the align detection device and high precision positioning device)

Applications:

Specialized in die-cutting of cardboard below 1mm, especially for various high-grade and fine printed materials, such as cigarette boxes, wine boxes, gift boxes, small home appliance boxes, cosmetic boxes, etc. Equipped with the latest servo-driven paper feeder.

Features:

Paper feeding section

*The original Japanese high-speed feeder feeds cardboards one by one into the infeed section by vacuum adsorption.

*The air pressure and suction volume of vacuum adsorption can be adjusted according to the thickness, condition and shape of the cardboard.

*The head part of the flyer is equipped with micro-adjustment devices to ensure the precision of paper feeding.

*The triple safety protection device prevents the flyer head from collision.

Die-Cutting Section

*Quick change automatic locking system can save the time of changing the board, there is a separate four-corner pressure adjustment device to make the pressure more balanced, so that the service life of the knife and die can be increased by more than 20%.

*Sensors are set on the side of die-cutting steel plate to prevent pushing out of place and causing skewed indentation line leading to defective products.

*Adopting aviation aluminum alloy tooth row and positioning mechanism, tooth piece with 2-piece design, silicon manganese alloy manufacturing durability is more than twice of peer products.

*Special processing chain of Japan DID company, each chain is stretched and processed by Japan original factory, and paired to provide a long service life.

*Adopting electromagnetic clutch imported from Japan original factory, it is fast to split and close, and can work normally without extra air source.

Stripping Section

*The clearing frame adopts the structure of three frames: upper, middle and lower.

You can choose the cleaning needle or male or female plate for cleaning.

*With the intermediate positioning structure of the die-cutting section, the clearing section also adopts the intermediate positioning structure for plate loading, which simplifies the plate changing procedure, ensures accurate positioning of plate changing and improves the production efficiency.

Paper collecting section

*Independent cam linkage drive mechanism, synchronized with the time divider to make the take-up more neatly. The take-up section is used to pile up the die-cut paper. When the tooth row grips the paper and stops at the take-up section, the unloading lever pushes the paper down.

*A row of brushes will die-cut cardboard fall smoothly, and play for the product to eliminate static electricity.

*The paper is neatly stacked on the trailing shelf after being organized by the paper trimmer.

*It is equipped with batch insertion counting function and auxiliary splicing table, and can realize non-stop machine paper collection.

Case:

(AP-1060-TSB)

(AP-1060-TBS)

Visit our Competence Center in China to discover the NANTAI-AP-1060I-TBS die cut cutter first hand, subscribe here.

Copyright © Foshan Nantai Precision Machinery Technology Co.,Ltd. All Rights Reserved