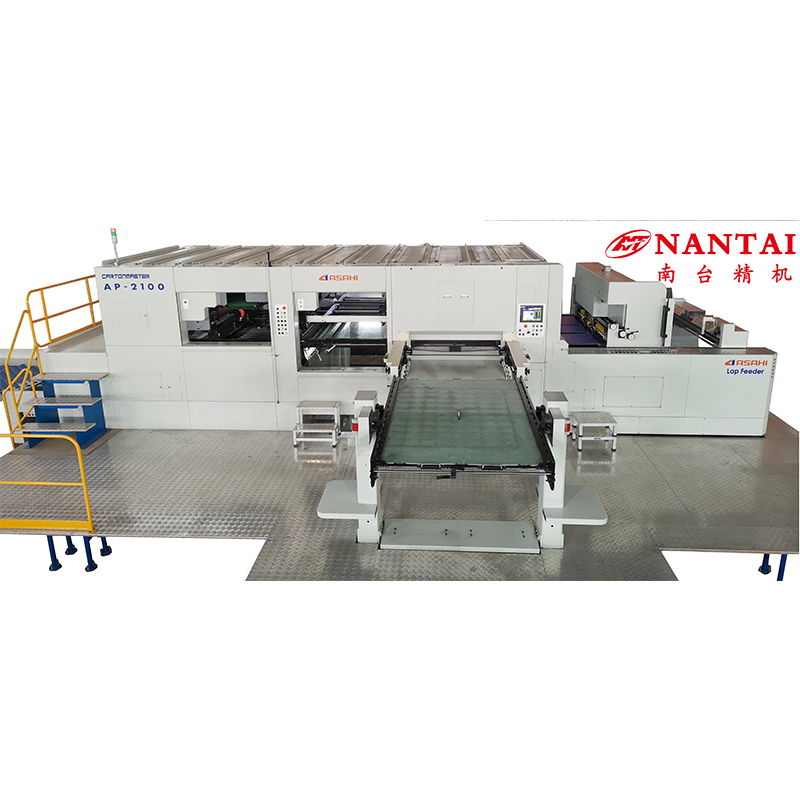

Best 4 Flat Bed Die-Cutters for the Corrugated box manufactures in Farance

Are you a cardboard box manufacturer in France? Seeking a dependable flatbed die-cutter to slash your production time and deliver efficiency, speed, safety in your operations? No problem as we will be showing you with top 4 flatbed die-cutters that were made to measure!

Advantages:

When you choose to invest in flatbed die-cutters, your manufacturing business can significantly benefit from it! This equipment is essential for increasing the efficiency, productivity and ultimately profits. Flatbed die cutters can quickly boost your production output by allowing you to process a larger volume of sheets faster. Furthermore, their contours ability in cutting cartons of any sizes Helps you to cater for customer specific requirements. A flatbed printer can minimize wastage by manufacturing products that are accurately cut to size, removing scrap material effectively.

Innovation:

Throughout the years, technology used in flatbed die-cutters has improved dramatically as well and this year certainly doesn't lag behind. Most systems today have user-friendly interfaces, which anyone with low tech-savviness can easily use. By using advanced software to direct the cutting, intricate shapes and designs are easily processed with flatbed die-cutters. For example, some models have a self-feeding operation that compensates for the thickness of corrugated material by enabling straightforward feeding at any time during production with automatic feed systems.

Safety:

The safety in a working environment is paramount for any operation, and flatbed die-cutters are designed with many safeguards to protect the operator during use. They have a safety sensor, which on detecting any unauthorized hand insertion during functioning stops its operation to avoid accidents. Some models also include two-hand starting mechanisms, emergency stops and safety gates which would increase its level of safety.

Use:

One of the things that put flatbed die-cutters in high demand is how they are relatively easy to use, meaning any manufacturer can get it and start operating it on minimal training. So you can use the machine immediately upon purchase. But all safety features must be installed & working properly before starting the operations. Cleaning, lubrication and part maintenance on a regular basis are necessary in order to increase the machine-life besides increasing its effectiveness.

Application:

Beyond the making of corrugated boxes, flatbed die-cutters are adopted across industries because they enable increased versatility. While those are the uses these machines for carton making, they can also be used to make envelopes or graphic arts displays as well. Customers can use them to make products in different shapes and sizes Constraint actuation circuits Advice The customer side of the Ural Cup realization

Conclusion:

In conclusion, flatbed die-cutters are a significant investment for corrugated box manufacturers in France that facilitates them with increased efficiency and productivity along with heightened profits. Their continuing evolution to maintain industry-best machinery allows for a smooth, safe operational experience. Since these tools serve a myriad of industries, they can be easily modified and utilized by manufacturers to meet their specific production needs. Flatbed die-cutting systems are adaptable machines that offer a dependable solution for business looking to make the most out of their manufacturing operations. It is important to know what the machine would be used for before making your purchase, as well as any quality standard specifications and after-sale services offered by the manufacturer.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

IS

IS

HY

HY

EU

EU

BN

BN

LO

LO

MY

MY