NANTAI-ASAHI-AP-165EII-Automatic Die Cutting Machine-Left and Right Handed Common Platform

Machine Performance Features

*Specially designed for corrugated boards, equipped with the latest servo-driven paper feeding system.

* Accurate die-cutting accuracy can be obtained from E to AB corrugated.

*Waste removal system and gripper edge waste removal device for complete waste removal.

*Excellent adaptability to both large and small lot sizes.

*Reliable safety performance, double safety device design (air brake and power failure stop device).

*All operating controls are located outside the machine for safety and reliability.

* The newly developed take-up unit can be well adapted to one version of multi-mode products.

* Highly efficient production, accurate die cutting and creasing.

Paper Feeder Section

*The latest servo-driven belt suction paper feeder (leading edge paper feed method).

*Ensures smooth feeding of large cardboard, greatly improving operability and productivity.

*High feeding accuracy and low damage to cardboard strength.

*The specially designed board leveller prevents the board from crossing the front stop for curved boards.

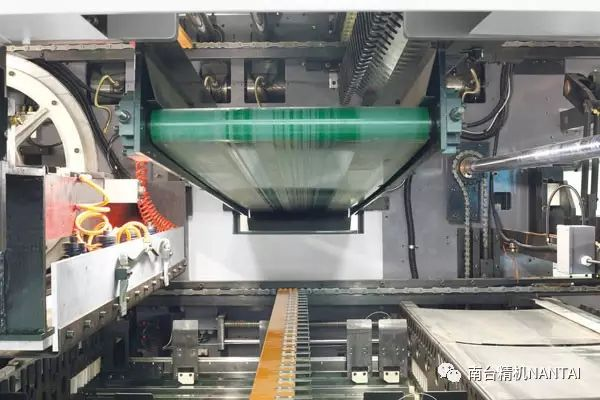

Die-Cutting Section

*Special crankshaft gear transmission and forced lubrication system, using high-precision and high-quality alloy steel gears developed and designed in Japan.

*The gears are hardened and ground for high precision, high strength, good abrasion resistance and smooth operation.

*Gripper row power transmission adopts original imported precision intermittent cam splitter, reliable and stable.

*Asahi Machinery specially designed nail gripper for warped and heavy cardboard, stable and durable.

Scrap Removal Section

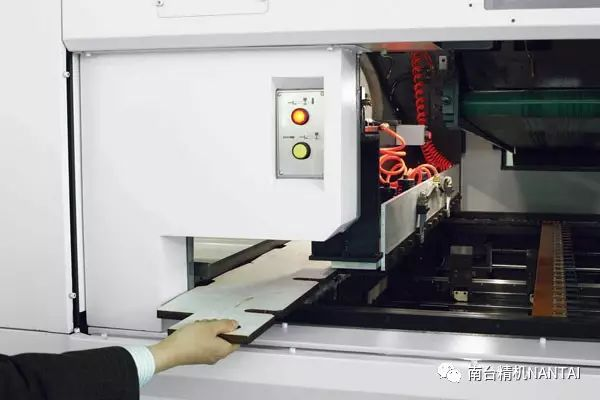

*Quick mould installation method, the operator does not need to enter inside the machine, but only work on the outside of the machine.

*Convex and concave moulds are inserted directly from the operator's side and the handle is locked. It saves time and ensures safety.

*The upper and lower frames ensure that the wooden moulds do an excellent job. Convex and concave moulds move up and down in unison for more accurate and thorough waste removal.

*Transparent plastic film is installed between the die-cutting section and the lower frame to prevent paper from falling off. The paper barrier film is adjusted by moving the handle according to the size of the assembly line direction of the wooden mould.

Knock Out Device

*The knockout plate is inserted directly from the operating side and automatically locked at once by a cylinder.

Edge Waste Removal Device

*Gripper edge waste is removed from the gripper pegs and sent to the outside of the machine via a conveyor belt for automatic discharge.

Batch-type Paper Collecting Section

*Front stopper, side stopper device, and rear stopper ensure neat paper.

* According to the size of the direction of the product line, the motor drive moves the side stopper and the rear stopper fence to match.

*Motor-driven paper receiving table for easy and quick setting.

*Servomotor control of temporary paper catching device makes paper receiving easier and faster.

* Calculate batch type stacking output.

To learn more about NANTAI for inline automatic flated die cutter machine, please follow this link.

Visit our Competence Center in China to discover the NANTAI-AP 165EII first hand, subscribe here.

Copyright © Foshan Nantai Precision Machinery Technology Co.,Ltd. All Rights Reserved