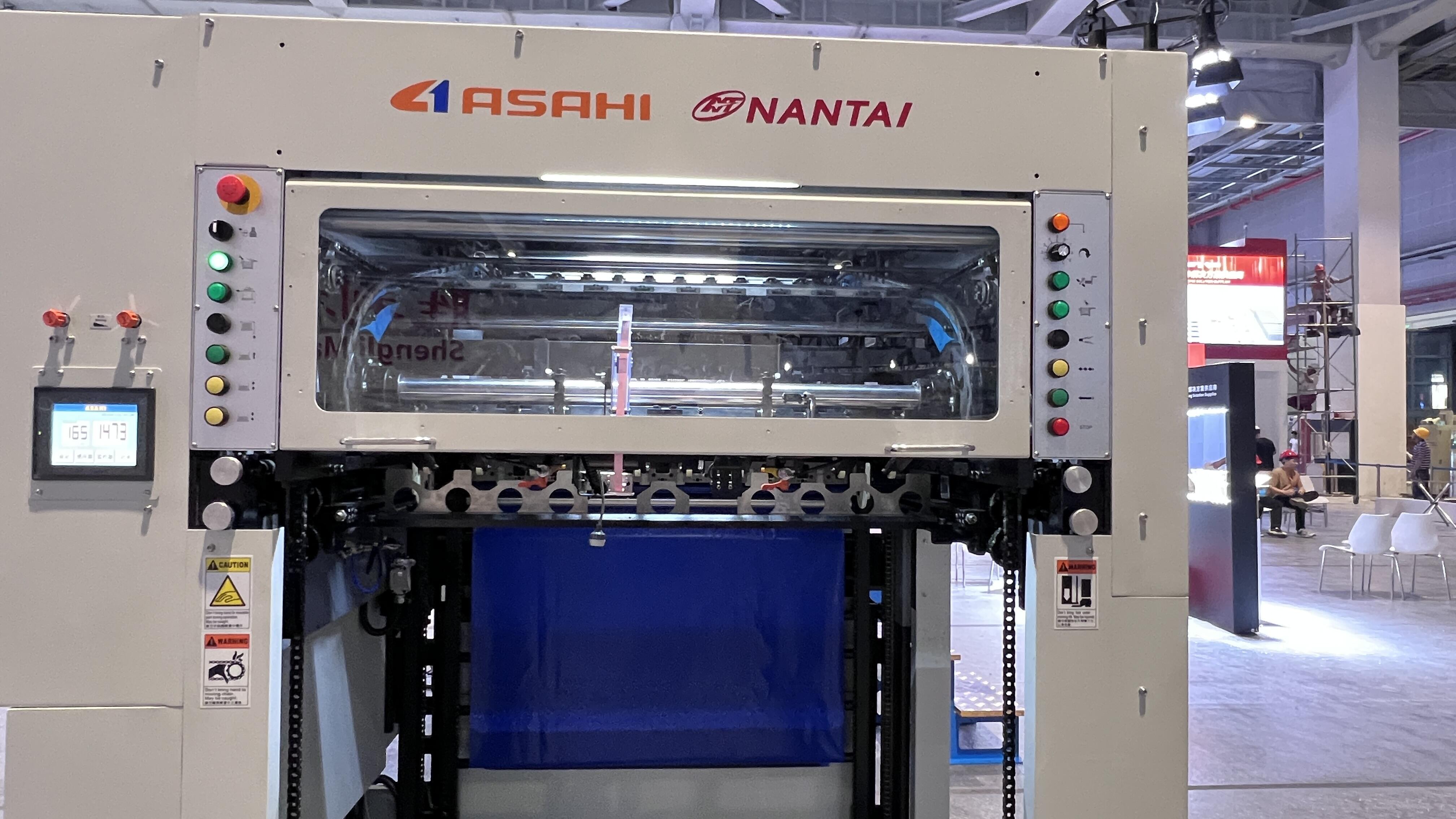

Ultimate productivity, flexible ASAHI-NANTAI AP-1060II-TS&AP-1060II-TBS

Features

●Top Suction Feeder: to ensure that the color printed surface is not scratched;

●Left-hand configuration;

●Accurate cutting registration for all paper grades;

●Designed s accurately at high speed;

●Smooth actioto transfer sheetn of the gripper bar drive to avoid sheet damage;

Competitive Advantage:

Paper Feeder

Top Feeder with accurate side and front lays for sheet positioning

Servo driven feeder to ensure that the timing between the press and the feeder remain constant. Sheet timing control at the feeder for variable materials such as thin paper and coated material. Push or Pull type side lay with micro adjustment for precise sheet positioning.

Press unit

Reinforced press structure for High-speed and High pressure production. Chase clamp with Air lock system. Simple "One touch Cross bar" is used to reduce the set up time.

Die-Cutting Section

Quick-change auto-locking system reduces the time for changing the boards. Separate four-corner pressure adjustment device makes the pressure more balanced and improves the life of the die by more than 20%.

Sensors are installed at the edge of the die-cutting steel plate to prevent the indentation line from being skewed and causing defective products if it is not pushed into place.

Adopting aviation aluminum alloy tooth row and positioning mechanism, tooth piece with 2-piece design, silicon-manganese alloy manufacturing durability is more than twice the peer products.

Japan DID company special processing chain, each chain through the Japanese original factory stretch processing, and paired to provide, long service life.

Adopting electromagnetic clutch imported from Japan, it is quick to separate and close, and can work normally without extra air source.

Stripping Section

The upper and lower stripping frames move in order to create a wide gap and for sheet transfer at high speed. Bottom pins can be added to guarantee the removal of small waste at high speed. Blanking system available(Option, and for TSB model).

Suitable for:

from thinner paper to even corrugated board,carton board, heavy solid board, corrugated board.

Specifications:

|

Model |

AP-1060Ⅱ-TS |

AP-1060Ⅱ-TBS |

|

Max. Sheet Size: |

1060x760mm |

1060x760mm |

|

Min, Sheet Size: |

400x270mm |

400x270mm |

|

Max. Cutting Size: |

1050x750mm |

1050x750mm |

|

Sheet Thickness Range: |

0.1~1.5mm Cardboard, Micro-corrugated board ≤4mm |

0.1~1.5mm Cardboard, Micro-corrugated board ≤4mm |

|

Min. Gripper Size: |

8mm(Gripper) |

8mm(Gripper) |

|

Max. Speed: |

8000i.p.h |

8000i.p.h |

|

Stripping Type: |

Middle and three sides stripping |

Finished products blanking, middle and four sides stripping |

|

Max. Operation Pressure: |

250tons |

250tons |

|

Required Power Supply: |

21.5KW |

28KW |

|

Dimension(LxWxH): |

5761x4436x2450mm |

6970x4436x2460mm |

|

Machine Weight: |

13tons |

14.5tons |

Visit our Competence Center in China to discover the NANTAI-AP-1060TS die cut cutter first hand, subscribe here.