The Fantastic World of Die Cutters

Are you looking for a tool that can make your creative projects easier and more efficient? Look no further than a die cutter. This amazing Nantai tool can cut and shape a variety of materials, making it perfect for crafters, artists, and anyone who loves to create. We will explore the world of die cutters, discussing their advantages, innovations, safety, use, and service.

There are many advantages to using a die cutter. First and foremost, it can save you time and effort. Nantai Die cutters can cut and shape multiple pieces at once, allowing you to create identical pieces quickly and easily. This means you can complete your projects in a fraction of the time it would take to cut and shape pieces by hand. Additionally, die cutters can cut a variety of materials, including paper, fabric, vinyl, and more. This versatility allows you to tackle a wide range of projects, from card making to scrapbooking to home decor.

Die cutters have come a long way since their inception. Modern die cutters are equipped with innovative features that make them even more efficient and user-friendly. For example, some Nantai manual die cutter come with built-in scanners that allow you to scan images and convert them into cutting files. Others feature automatic blade adjustment, so you don't have to worry about manually adjusting the blade depth. These features make it easier than ever to create intricate designs with ease.

Safety is always a top priority when working with any kind of machinery, and die cutters are no exception. Modern Nantai die cutter are equipped with safety features that ensure the user's safety while in operation. For example, many die cutters have sensors that prevent the machine from running if the cutting mat or plates are not inserted correctly. Additionally, some models have safety locks that prevent the machine from operating unless the user has pressed a specific button or lever.

Using a die cutter is relatively uncomplicated. First, select the material you want to cut. Next, choose the shape or design you want to cut from the Nantai die cutter library or create your own design. Place the material on the cutting mat, and insert the mat into the die cutter. Finally, activate the die cutter, and it will cut the material to the desired shape.

die cutter die-cutting equipment cardboard mainly used groups tech companies, well as secondary packaging factories. products sold over 50 countries we serve over 20,000 clients around world.

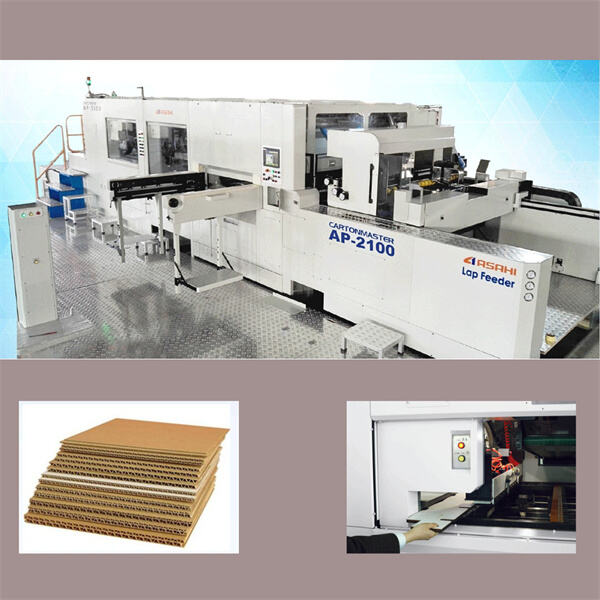

primary business company manufacturing flatbed die-cutting machine equipment as well technology cardboard microcorrugated, corrugated, cardboard, paperboard. company's current main products flatbed die-cutter offset cardboard(die cutter); flatbed cutter micro-laminated board (Top SuctionFeeder); flatbed die-cutter corrugated cardboard boxes (Bottom Suction Lead Edge Feeder) flatbed die-cutter corrugated carton box (Production Line), four series more 20 equipment products.

company received lS0 CE certificate well as 4 patents. recognized "Safety Production Standardisation level 3 die cutter". High-precision feeding paper well as high-precision die cutter high-speed operation. Waste removal system, finished products collection, optional collection methods Receiving table, etc. Support technical assistance one year warranty service.

Nantai boasts manufacturing facility 60,000 square metres. centre that four major product die cutter, more 20 models thousands spare parts meet demands customers. Nantai received numerous patents. 2004, Nantai technical cooperation famous ASAHI Japan manufacturing centre latest technology high quality automatic die-cutting equipment.

To get the most out of your die cutter, it's essential to follow a few simple guidelines. First, always use the correct size cutting mat and plates for your machine. Using the wrong size can cause damage to the machine and the material you're cutting. Second, clean your machine regularly. Over time, debris and buildup can accumulate on the cutting mat and plates, compromising the Nantai die cutter letters machine's performance. Finally, always follow the manufacturer's instructions for blade adjustment and maintenance.

As with any machine, it's crucial to have access to reliable service and support in case something goes wrong. When shopping for a Nantai die cut cutter, look for a model that comes with a warranty and a customer support team that can assist you with any issues you encounter. Additionally, some manufacturers offer repair services, so if a component on your machine fails, you can have it repaired rather than replaced.

When it comes to die cutters, quality should be a top consideration. Look for a machine that is built to last, with durable components and a solid construction. Additionally, consider the machine's cutting capabilities. Can it cut a variety of materials and shapes? Does Nantai die and cutter come with a variety of cutting mats and plates? Finally, read customer reviews and ratings to get an idea of the machine's overall performance and user satisfaction.

Copyright © Foshan Nantai Precision Machinery Technology Co.,Ltd. All Rights Reserved