Businesses have never handled printing and cutting tasks as efficiently, precisely or productively until the emergence of Cutter flatbeds. With the wide variety of cutter flatbeds saturating (or dominating) today? The choice can understandably seem daunting. This post combines our extensive research as field experts in the area with many years of experience to provide you a comprehensive guide full of recommendations that help preventing any issues during your process, so once it comes we hope after reading this article decision makings improves sales performance and guaranteed assistance thinking or even helping to get through buying portable Nantai die cutter suitable for businesses.

The world of cutter flatbeds are rich with cutting edge technology to increase accuracy and productivity. So, we are going to take a look back at the latest tech advances in Nantai manual die cutter.

One of the most striking characteristics of modern cutter flatbeds are they cut materials automatically into specific shapes and sizes, obviating for manual intervention. This can help speed the process of laminating cutting and also improve accuracy too while working with a labor intensive method securing edges.

Incredible precision cutting - These next-level models are designed to ensure flawless accuracy in the cut each and every time. Cutter flatbeds come with a set of highly sophisticated laser-guided systems that cut materials with razor sharp precision regardless if the shape is complex.

It Enables High-Speed Cutting- Utilizing the latest in technology, modern cutter flatbeds can cut materials that move as quickly amazing speeds which reduce not just time but labor demands too.

Cutting With Your Cutter Flatbed to Optimum Efficiency and Performance

Utilization is the key to some of your cutter flatbed, so you have to use it well if you want everything that has been unlocked with this incredible machine. Workmanship Nantai butterfly die cutter.

Use High-Grade Materials: By using high-quality materials, you can reduce errors and wastes during the cutting process thereby making it highly efficient when maximizing output whilst minimizing time and labor costs.

Organize and Schedule Cutting Tasks: To achieve the highest possible output from your cutter flatbed, it is essential to plan in detail all cutting tasks you have through careful scheduling.

Regular maintenance: For you cutter flatbed to remain in the peak performance condition; it is essential that regular cleaning, lubrication, and replacement of worn-out parts are carried out.

Choosing the Right Cutter Flatbed for Your Business depends on your requirements and available budget. Here are some things to keep in mind while selecting a cutter flatbed:

Cutting Table Size: The first thought on the cutting table determines what dimensions of materials can be handled within. This larger cutting table fittingly allows for bigger materials, while a smaller one will restrict you to the size of material.

Cutting Speed: What really matters when processing materials using a cutter flatbed is the cutting speed. Fast cutting speed for rapid output machine.

Comparison: With price points that vary greatly, the more a machine costs, usually corresponds with more features and capabilities. Consider your budget and choose a machine that has the features you need at an affordable cost.

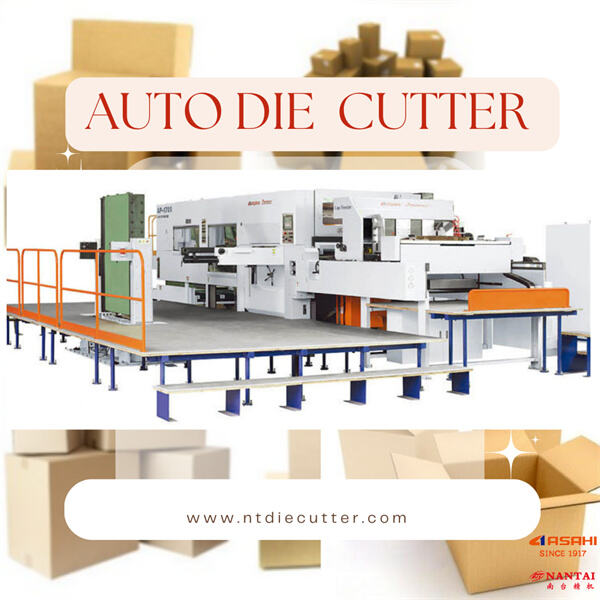

Cutter flatbed received four patents lS0 CE certification. addition, company, recognised "Safety Production Standardisation Level 3 Enterprise". High-precision paper feeding, high precision die-cutting high-speed operation. Waste removal system, finished products collecting, additional collection methods Receiving table, etc. We offer technical assistance and a one year warranty.

Nantai boasts manufacturing facility 60,000 square metres. centre that four major product Cutter flatbed, more 20 models thousands spare parts meet demands customers. Nantai received numerous patents. 2004, Nantai technical cooperation famous ASAHI Japan manufacturing centre latest technology high quality automatic die-cutting equipment.

die-Cutter flatbed machines made cardboard mainly used groups technology firms, companies field secondary packaging factories. products exported over 50 countries, serve than 20,000 customers around world.

main business company produce automatic flatbed cutting machine technology well as equipment cardboard, microcorrugated board, corrugated paperboard carton cardboard. current products offered company include flatbed cutter offset cardboard(Top Suction Feeder); flatbed die-cutter micro laminated board (Top SuctionFeeder); flatbed die-cutter corrugated paper box (Bottom Suction Lead Cutter flatbed); flatbed die-cutter corrugated carton box (Production Line), four series include 20 equipment items.

Copyright © Foshan Nantai Precision Machinery Technology Co.,Ltd. All Rights Reserved